Cold Plates

Coolant circulates through cold plates, mounted directly to server processors, to remove heat at its source and cool data centers more efficiently.

Benefits

- Standard cold plates, designed for major server manufacturers, make installation easy.

- Custom cold plates can be designed and delivered quickly, for all server types.

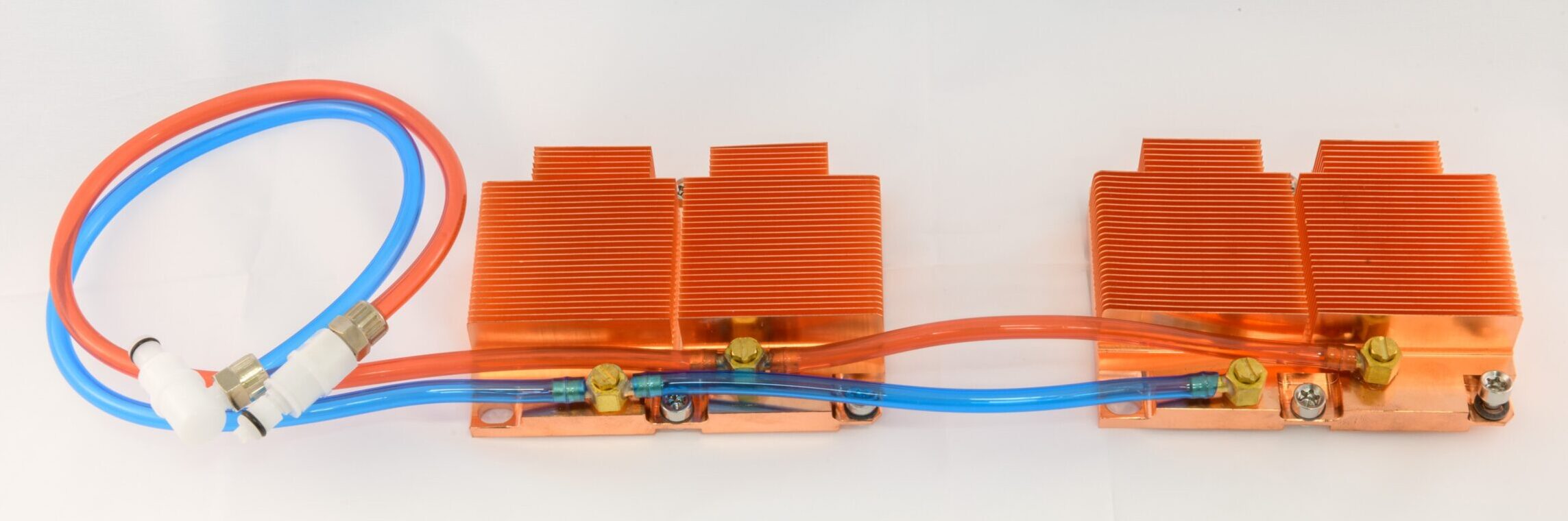

- The hybrid cold plate design uses fins for additional air cooling as a temporary backup, allowing the system to continue operating during service, testing, and upgrades.

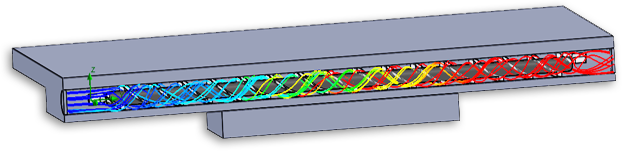

- Using channels in the cold plate, called turbulators, mixes cooling fluid to improve heat absorption.

Turbulator Technology

Chilldyne uses turbulators, placed inside flow paths (channels) in the cold plate, to mix the coolant and increase thermal transfer. Warmer liquid on the outside of the channel is mixed with cooler liquid in the center to improve heat absorption. This also allows data center operators to fine-tune the liquid flow and set the optimal balance between heat removal and pressure required for each server.

Hybrid cold plates deliver cooling fluid direct to the chip for the best possible performance while still retaining the air cooling fins on top of the cold plate. This allows the cold plate to also serve as an air-cooling backup. If the cooling system needs to be taken off line for service, the servers can still perform on air cooling. This reducers down time and simplifies service.