Chilldyne’s Comprehensive Approach to Reliable Direct Liquid Cooling

The rapid advancement of generative AI has led to a surge in high-performance computing and data center heat loads. Liquid cooling has emerged as a powerful solution for managing these increasing thermal challenges. At Chilldyne, our extensive experience in this emerging field has enabled us to develop a comprehensive approach that ensures reliable, efficient, and safe liquid cooling operations. By combining advanced technologies, engineering expertise, and best design practices, we deliver solutions that not only enhance performance but also maintain the highest standards of reliability and safety.

In this article, we'll explore four key strategies that Chilldyne employs to ensure the reliability and efficiency of our direct liquid cooling solutions.

Strategy #1 - Negative Pressure Liquid Cooling: Eliminating the Risk of Leaks

Chilldyne's negative pressure technology is the foundation of our leak-proof liquid cooling solution. By creating a vacuum within the system, we eliminate the risk of leaks, even in the event of component failures such as degraded o-rings. This technology acknowledges that no component is perfect and maintenance is inevitable—just as we maintain our cars, homes, and airplanes. However, with Chilldyne's negative pressure system, leaks are prevented before they can occur, protecting your hardware and ensuring uninterrupted data center operations.

In fact, if maintenance is needed on a node and components need to be replaced, you can do so easily without shutting down the entire system. Simply disconnect the cooling lines from the server – thanks to the negative pressure, there will be no leaks. This hot-swapping capability minimizes downtime and allows for seamless maintenance without compromising the integrity of your liquid cooling system.

Strategy #2 - Automated Coolant Quality Control: Proactive Maintenance

Chilldyne's ACQ (Automated Coolant Quality) system continuously monitors and maintains optimal coolant conditions, proactively addressing risks like biofilm growth, contamination, high TDS, and corrosion. By automatically dispensing necessary additives, ACQ prevents issues like cold plate clogging, extending component lifespan and minimizing downtime with minimal manual intervention.

Strategy #3 - Fail-Safe Design with N+1 CDU Redundancy

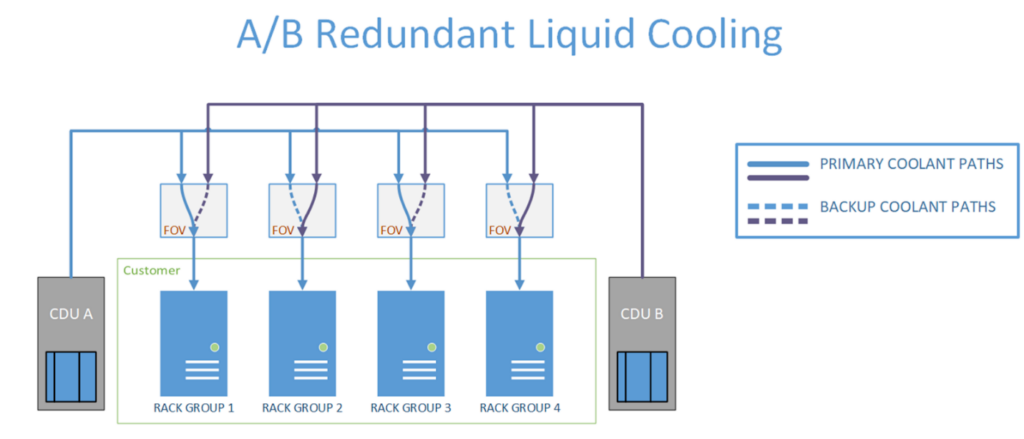

Figure 1: An A/B redundant liquid cooling system with N+1 setup. Each rack group is connected to both CDU A and CDU B through primary and backup coolant paths.

Chilldyne's systems incorporate fail-safe redundancy measures, such as N+1 CDU design and automatic switchover valves, ensuring uninterrupted cooling even in the rare event of a component failure. This redundant design acts as a dependable safeguard for your data center's cooling needs, preventing downtime and protecting critical hardware. If an anomaly is detected in a CDU's operation, the system automatically switches to a backup unit. While a single CDU failure is uncommon with proper maintenance, multiple simultaneous CDU failures are exceptionally rare and nearly non-existent, making Chilldyne's redundant design an invaluable asset for your data center's cooling system.

Strategy #4 - Hybrid Cooling: Liquid-Cooled Cold Plates with Backup Air Cooling

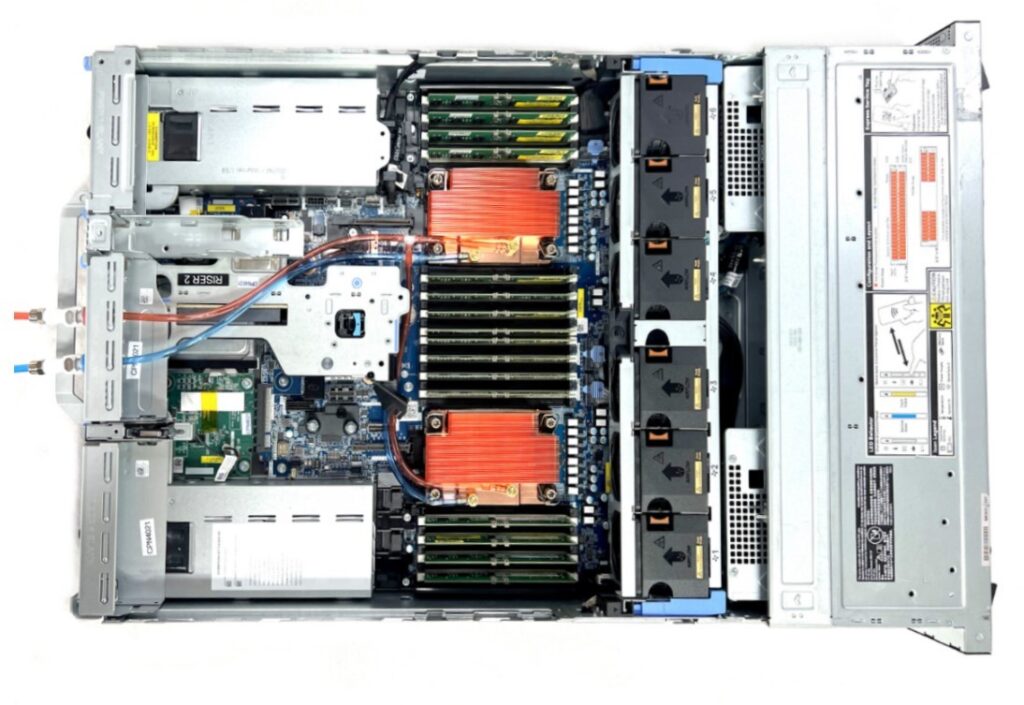

Figure 2: A Dell R760xp server modified for direct-to-chip liquid cooling, with copper air/liquid hybrid cold plates prominently visible. Notice the air fins on the cold plates for backup cooling.

In some scenarios, Chilldyne employs hybrid air/liquid cooling cold plates equipped with fans. This innovative design ensures that if the liquid cooling system is compromised, the fans can prevent overheating by providing a backup cooling method. Although the system may experience throttling due to reduced cooling capacity, it will continue to operate, preventing complete downtime. This hybrid approach offers an additional layer of protection, ensuring your data center remains functional even in the face of unexpected cooling challenges.

Cost of Downtime in Data Centers

At Chilldyne, we operate under the principle that "the only good downtime is no downtime." We understand that every minute of downtime can cost businesses dearly. According to ITIC's survey data in 2021, 91% of organizations report that a single hour of downtime costs their business over $300,000, while 44% of enterprises state that one hour of downtime can lead to losses ranging from $1 million to over $5 million.

To put this into perspective, consider the following: if an insurance company were to provide coverage for these potential losses, the premiums would be astronomical. The high cost of downtime underscores the critical importance of reliable cooling systems in data centers.

Conclusion

Chilldyne's comprehensive approach to direct liquid cooling addresses the unique challenges faced by high-performance computing and data centers. By combining advanced technologies, proactive maintenance, fail-safe design, and hybrid cooling solutions, we ensure that your data center remains operational and protected, even in the face of unexpected cooling challenges. With Chilldyne, you can trust that your cooling system will deliver the reliability, efficiency, and safety necessary to support your mission-critical applications.