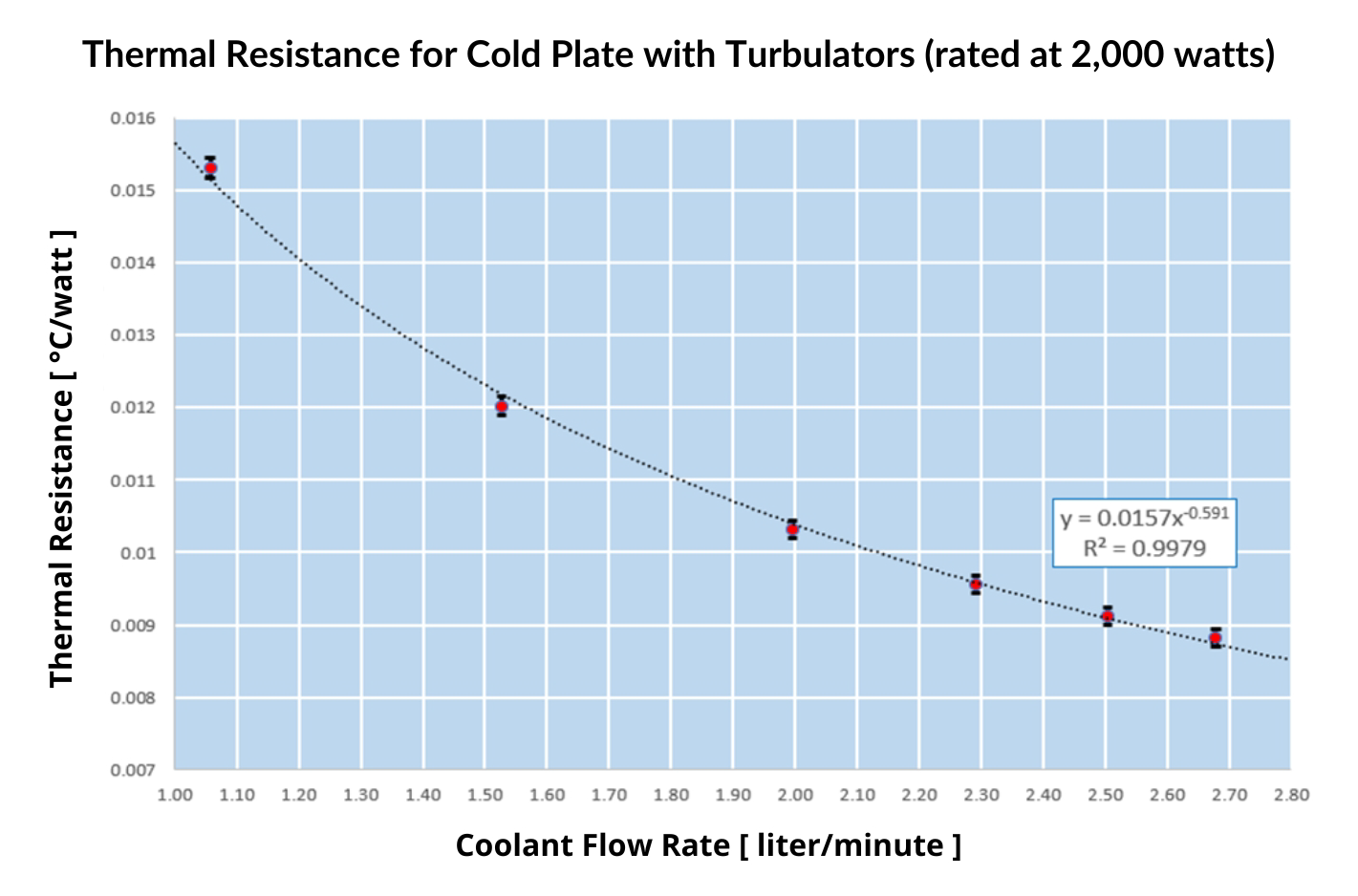

Thermal Resistance Data for 2,000-Watt Cold Plate with Turbulators

Chilldyne’s liquid cooling technology, featuring cold plates with turbulators, provides a reliable and efficient solution to manage the high heat loads from modern HPC and AI applications. This graph highlights the thermal performance of our 2,000-watt cold plate, showing how advanced turbulator technology significantly improves heat transfer.

Figure 1: Thermal performance of the Chilldyne cold plate with turbulators. The coolant is pumped under negative pressure, maintaining the fluid in a single-phase state while eliminating the risk of coolant leaks.

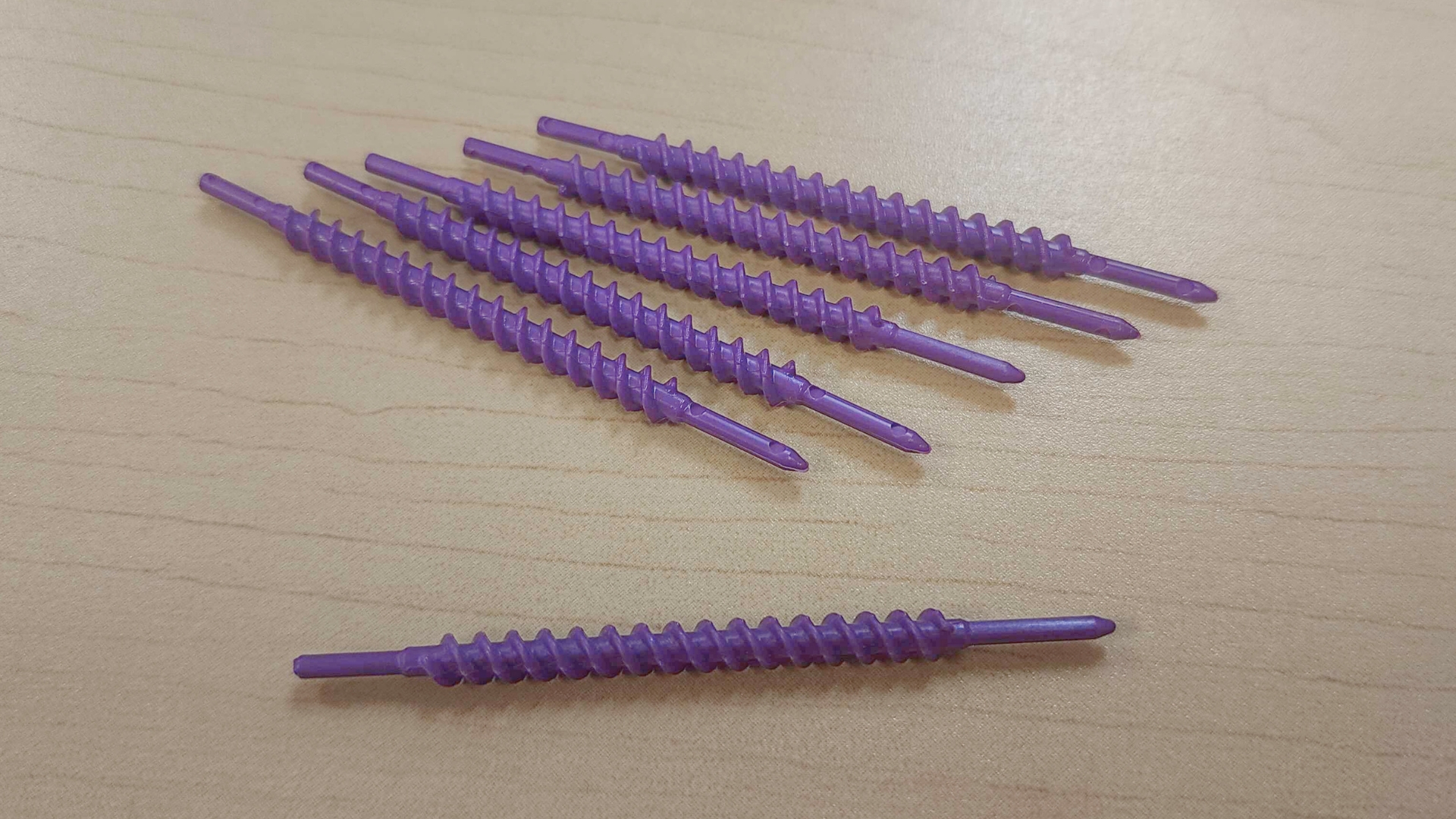

Chilldyne uses turbulators inside the flow channels of the cold plate to mix the coolant and enhance heat transfer. The turbulators significantly reduce thermal resistance, enabling more efficient cooling compared to standard cold plate designs with laminar flow.

Figure 2: A turbulator design. The turbulator is optimized to increase the heat transfer coefficient through the cold plate.

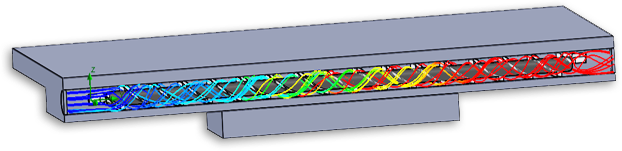

Figure 3: Computational fluid dynamics (CFD) simulation of a turbulator-enhanced flow channel inside a cold plate, showing improved heat transfer.

To learn more about Chilldyne’s liquid cooling technology or to schedule a cooling assessment, contact us today.